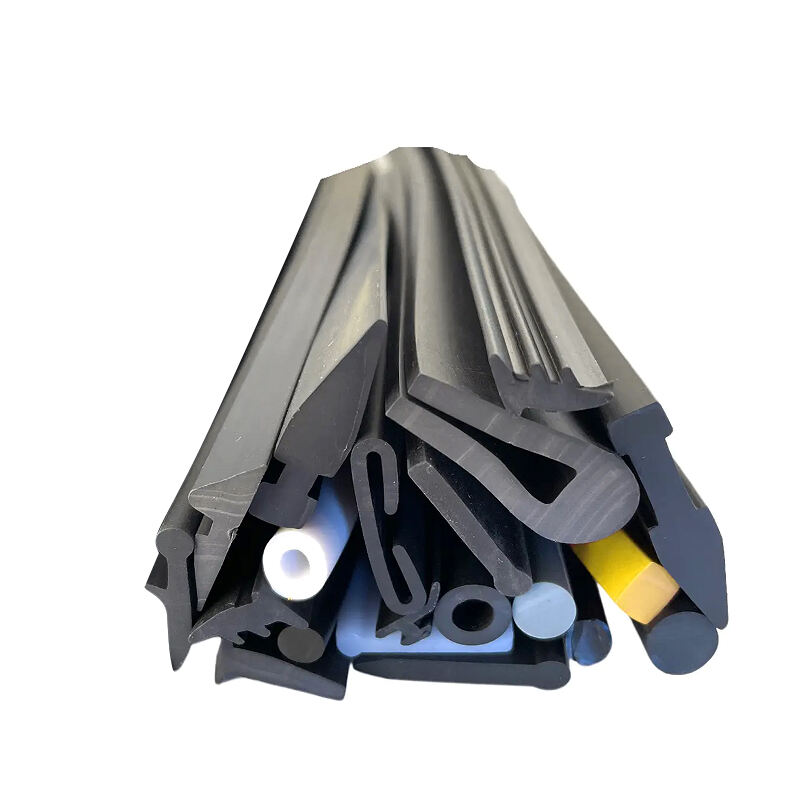

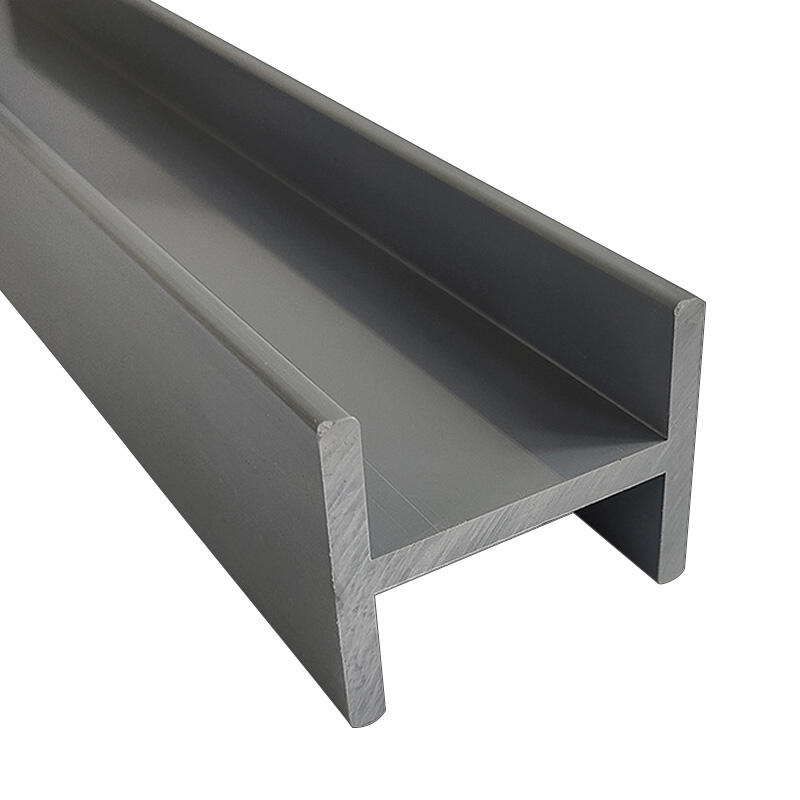

Shenzhen Xinhaiwang Technology Co., Ltd.'s extruded strips are highly durable, crafted from premium materials like EPDM, silicone, and NBR that resist abrasion, weathering, and chemical exposure. The extrusion process ensures consistent molecular structure, enhancing tensile strength and elasticity. For example, EPDM extruded strips withstand extreme temperatures (-50°C to 150°C) and ozone, maintaining flexibility for 10+ years in outdoor use, while silicone strips resist high heat (up to 200°C) and retain shape after repeated compression. Their durability is further validated by FDA/ROHS certifications, making them ideal for long-term use in construction, automotive, and industrial applications with minimal degradation over time.Extruded strips are widely used across industries as a result of their strength and versatility. Here at ShenZhen XinHaiWang Technology, we take advantage of quality extrusion processes in stripping that endures stress, temperatures and chemicals. Our extruded strips are aimed for the automotive industry, the medical field and machine building, as appropriate for the target environment. We only use the highest quality materials coupled with precision in our manufacture to enhance the durability of our products—making it suitable for projects with high-performance objectives.