Environmental Exposure and Chemical Resistance Needs

Selecting the right rubber materials for applications that face environmental exposure is crucial for durability and performance. Various environmental factors, such as UV radiation, ozone exposure, and extreme weather conditions, significantly affect rubber materials. For instance, ethylene propylene diene (EPDM) rubber is highly resistant to weather-related damage, making it an excellent choice for outdoor seals and gaskets. Chemical resistance is equally important, especially in applications where rubber gaskets encounter oils, solvents, and acids. Nitrile rubber (NBR), known for its exceptional oil resistance, is often used in automotive seals exposed to fuels. Statistics highlight that improper rubber selection leads to increased failure rates, especially under harsh environmental conditions. Industry standards, such as those by ASTM, provide guidelines for testing rubber materials' environmental resistance, ensuring they meet necessary durability criteria.

Temperature Range and Durability Requirements

In industrial applications, rubber materials must withstand specific temperature ranges to ensure functionality and longevity. Extreme temperatures can affect the elasticity and durability of rubber, leading to performance degradation. For instance, styrene-butadiene rubber (SBR) is valued for its heat resistance, making it suitable for car and truck tires. Data indicates that silicone rubber, due to its low thermal conductivity, excels in high-temperature applications but offers limited chemical resistance. When evaluating the long-term durability of rubber materials under various thermal conditions, it's essential to consider their thermal properties carefully. Best practices suggest conducting thorough evaluation tests to determine how temperature fluctuations might impact the rubber's structural integrity and performance over time.

EPDM Rubber Gaskets for Weather and Water Resistance

EPDM (Ethylene Propylene Diene Monomer) rubber is renowned for its excellent resistance to weathering and water, making it ideal for outdoor applications. Its robustness against ultraviolet (UV) radiation, ozone, and climatic extremes allows it to maintain performance in applications such as roofing and automotive weather seals. Many industries prefer EPDM gaskets due to their long-term reliability, even under continuous exposure to harsh environmental conditions. These qualities are often substantiated by certifications and lab tests adhering to industry guidelines, confirming EPDM's suitability for demanding environments.

Nitrile Rubber for Oil and Fuel Resistance

Nitrile rubber, or NBR, exhibits exceptional resistance to oils and fuels, thanks to its unique composition. This makes it a prime choice in the automotive and aviation industries, where the rubber needs to resist prolonged exposure to petroleum-based substances. Studies show its superior performance compared to other rubber types in these environments. Standard applications include gaskets, seals, and hoses. While there are alternatives like neoprene for oil resistance, nitrile rubber's efficiency and specific resilience in oil-based applications often make it the preferred material.

Silicone Rubber in High-Temperature Scenarios

Silicone rubber stands out for its thermal stability, which makes it the go-to material for high-temperature applications. Industries such as food processing and aerospace often utilize silicone rubber for its ability to remain flexible and durable across a broad temperature range. Despite its advantages, the higher cost of silicone compared to other rubber materials can be a drawback. This often necessitates a careful cost-benefit analysis. Nonetheless, performance data and testimonials from industry experts reinforce silicone rubber's efficacy, making it a worthwhile investment for high-temperature scenarios.

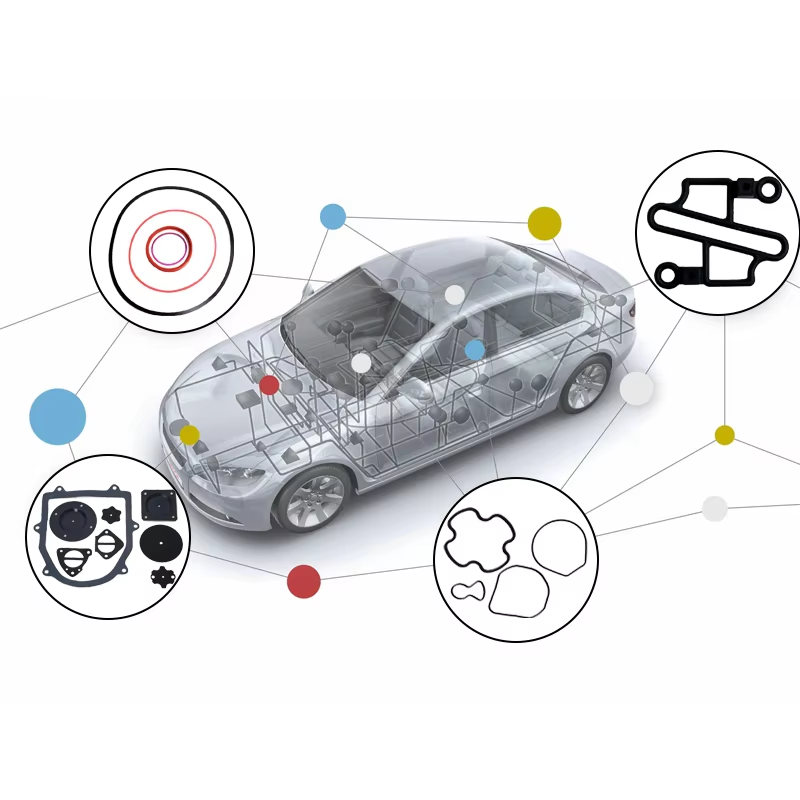

Choosing Between Round Rubber Gaskets and Custom Shapes

When selecting the right rubber gasket, understanding the application requirements is critical. Round rubber gaskets are often the go-to choice for standard sealing applications due to their simplicity in design and ease of installation. They excel in environments where uniform pressure is applied, making them ideal for general sealing tasks. On the other hand, custom-shaped gaskets offer versatility tailored to specialized needs, especially in complex assemblies or machining processes. These gaskets can be engineered to meet specific design criteria, enhancing performance in unique operational environments.

To decide between these options, one must consider the balance between cost-effectiveness and functionality. While round rubber gaskets offer a straightforward solution often at a lower cost, custom shapes provide the necessary flexibility for intricate applications. For example, a case study in the automotive industry demonstrated the success of using custom gaskets in spaces with irregular geometries, resulting in better seal integrity and leak prevention. Ultimately, the choice is determined by the specific sealing requirements of the application, considering factors such as shape, pressure, and environmental conditions.

EPDM vs. Other Materials for Long-Term Sealing

Choosing the right gasket material is essential for long-term sealing effectiveness. EPDM gaskets are renowned for their exceptional resistance to weathering and water, making them a superior choice in applications exposed to harsh environmental conditions. When compared to other materials like neoprene and nitrile, EPDM gaskets exhibit superior sealing abilities, particularly in settings requiring long-term durability and performance.

Environmental factors, such as exposure to UV radiation and varying temperatures, significantly affect the longevity and performance of gasket materials. Research indicates that EPDM gaskets maintain their integrity far better than neoprene over extended periods. Expert opinions often favor EPDM for its resilience in outdoor applications, citing its use in the automotive sector for weather seals as a testament to its effectiveness. Real-life applications, such as roofing and HVAC systems, often show enhanced performance when EPDM is selected, underscoring its suitability for enduring challenging conditions and ensuring long-term reliability.

Automotive Standards for EV Battery Seals

In the automotive industry, rubber materials used in electric vehicle (EV) battery seals must adhere to stringent standards, particularly those set by organizations like the Society of Automotive Engineers (SAE). These standards ensure that the seals possess critical properties such as heat resistance, chemical stability, and electrical insulation, which are essential for safety and performance in the highly demanding environment of EVs. With the rapid growth in EV production, which is expected to see a compound annual growth rate of over 20% in the next few years, the demand for reliable rubber seals has surged significantly. Industry experts point out that selecting the appropriate materials for EV applications is a complex challenge, as the materials must withstand diverse conditions while maintaining efficiency and durability.

Compliance with Potable Water Regulations

Rubber materials used in potable water applications must comply with specific regulations to ensure safety and performance, like NSF/ANSI 61. Compliance is crucial not only for maintaining public health but also for avoiding legal repercussions associated with non-compliance. Suitable materials for these applications include EPDM and silicone rubber, known for their excellent resistance to water and a range of temperatures. Recent technological advancements in rubber production aim to enhance material properties, such as improved resistance to microbial growth and chemical degradation. These developments are crucial in ensuring that rubber materials meet the increasingly stringent standards set for potable water applications, providing long-term safety and reliability.

Prototyping Under Simulated Conditions

Prototyping rubber materials under simulated conditions is crucial for ensuring product reliability and performance. By mimicking the environmental and operational conditions that a product will face, prototypes allow us to anticipate how materials might behave in real-world situations. Accelerated aging tests, for example, are employed to simulate the long-term effects of weather, temperature changes, and mechanical stress within a short period. These tests enable manufacturers to detect potential weaknesses and address them before product launch. Successful cases in the rubber industry, like the development of EPDM rubber gaskets, demonstrate that comprehensive prototyping can lead to products that excel under demanding conditions.

Assessing Wear Resistance and Lifespan

Assessing the wear resistance of rubber materials is paramount, especially for high-performance applications. Wear resistance tests, such as abrasion tests, are instrumental in predicting a product's lifespan by measuring how well a material withstands continuous use. By evaluating different rubber compounds, industries can select materials best suited for specific applications, like EPDM rubber gaskets, known for their durability against environmental wear. Industry standards established by ASTM guide these assessments, ensuring consistency and reliability. Additionally, insights from case studies underscore the importance of selecting the right rubber material to maximize performance and extend the product's longevity over time.

EN

EN