Vad är en yttålig tangentbordsförsegling och hur fungerar den?

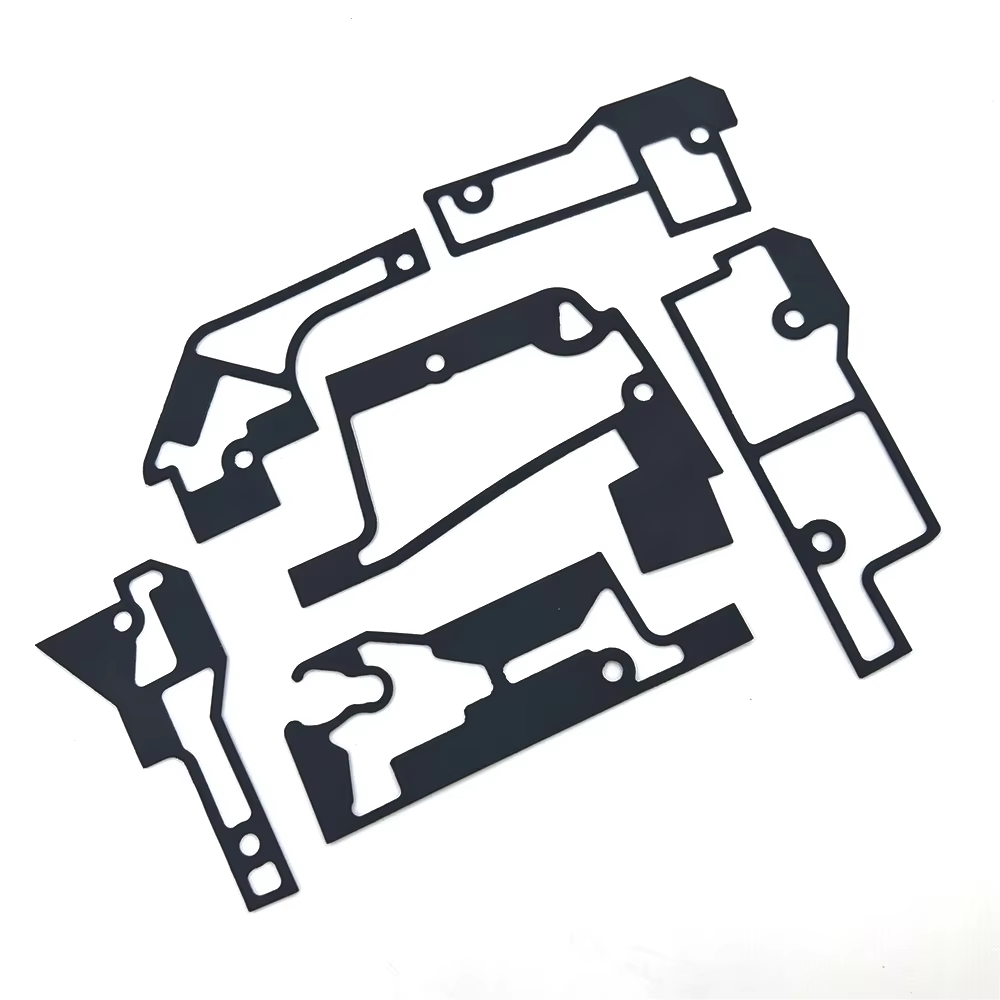

Yttåliga tangentbordsförseglingar fungerar som barriärer som förhindrar att damm och skräp kommer in i tangentbordet. Tillverkare använder vanligtvis material som silikontätningar, en sorts plastmaterial som kallas termoplastiska elastomerer samt speciella mikroskopiska beläggningar för att skapa skydd runt tangenterna. När någon trycker på en tangent trycks förseglingen ihop och återgår sedan till sitt ursprungliga läge, vilket håller ute det mesta dammet samtidigt som användaren fortfarande känner trycket eller motståndet som förväntas vid inmatning. Denna balans mellan skydd och användbarhet gör dessa förseglingar ganska viktiga för tangentbord som används i hårda miljöer.

| Dichtningstyp | Materialens sammansättning | Primär tillämpning |

|---|---|---|

| Elastomeriska tätningar | Silikon/Gummikompositioner | Industriella styrelser |

| Magnetiska tätningar | Järnlegeringar + polymerer | Medicinska enheters gränssnitt |

| Nanobelagda membran | Hydrofoba nanolager | Konsumentelektronik |

Försegla kontra oförsegla tangentbordsarkitekturer: Viktiga skillnader och prestanda

Industriella studier visar att täta tangentbord kan minska mängden damm som kommer in med cirka 98 % jämfört med vanliga tangentbord utan tätningsfunktion. De flesta traditionella tangentbordsdesign har små öppningar för luftflöde som låter damm sippra in med tiden. Täta versioner har istället särskilt designade tangenter med komplexa mönster som fångar upp dammpartiklar innan de når de känsliga delarna inuti. Resultatet? Mindre ansamling av gnisslande material på de små ledande banorna som ofta är orsaken till att tangenter slutar fungera ordentligt i vanliga tangentbord efter lång användning.

Bevisad effekt av yttäta tangentbord i dammiga miljöer

Hur yttäta tangentbord förhindrar mekaniska fel på grund av dammansamling

Tangentbordsytans tätningsmaterial fungerar som skyddande barriärer mot luftburna smuts som annars skulle ta sig in i de känsliga inre komponenterna. Tillverkade av flexibla gummiartade material kallade elastomerer kan dessa tätningsmaterial faktiskt fånga upp mikroskopiska partiklar i storleken 1 till 5 mikrometer i diameter. Det är ganska imponerande eftersom partiklar inom denna storleksintervall ofta är de främsta orsakerna till korrosion i tangentbordsswitchar och problem på kretskorten. När damm hålls borta innebär det mindre slitage på kontaktytorna och färre risker för farliga elektriska gnistor. Olika tester på industriella tangentbord har visat hur effektiva dessa enkla men viktiga tätningsmaterial verkligen är för att upprätthålla enhetens livslängd och prestanda.

Fallstudie: Industriella miljöer utan täta tangentbord och de resulterande felen

En 22 månaders utvärdering av icke-täta tangentbord i en cementtillverkningsfabrik avslöjade betydande driftproblem:

| Feltyp | Frekvens (månadsvist) | Påverkan av reparationsskostnader |

|---|---|---|

| Switchar som kantade | 18 incidenter | $420 |

| Korrosion i membranskretsar | 9 incidenter | $1 150 |

| Totala driftstopp i timmar | 37 timmar | 3 800 USD |

Underhållsprotokoll visade att 89% av alla fel berodde på infiltration av kalkstensstoft – helt förhindrat med rätt ytsejling.

Datainsikt: 78% minskning av fel med yttangentspjäll (IEEE 2022)

Forskning på 47 industrilokaliser visade att täta tangentspjäll ledde till:

- En 78% minskning av reparationer orsakade av partiklar

- Årliga underhållskostnader sparade $2 100 per arbetsstation

- 64% färre kritiska inmatningsfel under hög stoftbelastning

Dessa resultat bekräftar att moderna tätningsmaterial för tangentbord på ytan erbjuder skydd mot damm på IP6X-nivå utan att kompromissa med tangenttrycksprestanda – vilket gör dem oumbärliga i tillverknings- och läkemedelsmiljöer.

Tätningsmaterial för tangentbord på ytan och efterlevnad av miljöskyddsnormer

Förstå IP66- och IP68-klassificeringar för skydd mot damm och vatten

IP-klassningar, en förkortning för Ingress Protection, anger i grunden hur väl en enhet tål intrång av damm och vatten. Ta till exempel IP66 och IP68-klassningar. Den första siffran är alltid 6, vilket innebär fullständig skydd mot damm, även från väldigt små partiklar som är cirka 75 mikron eller mindre. När vi tittar på den andra siffran, så berättar den historien om vattenskyddet. En klassning på 6 innebär att enheten kan hantera kraftiga vattenstrålar utan problem, medan en klassning på 8 går längre genom att tillåta att enheten kan vara nedsänkt kontinuerligt. Alla dessa klassningar genomgår rigorösa tester enligt IEC 60529-standarder, så att tillverkare vet att deras produkter kommer att fungera tillförlitligt även i svåra förhållanden där damm och fukt är ständiga hot.

Hur yttangreppskonsstruktionen hos tangentbord uppnår IP-certifiering

Tillverkare som siktar på IP66- och IP68-certifiering förlitar sig vanligtvis på flera nyckelmetoder, inklusive kompressionssmålda silikontätningar, lasersvetsade sömmar samt dessa speciella hydrofoba membran. När det gäller IP68-certifieringskrav måste de flesta tangentbord tåla att vara under vatten i cirka en halv timme på en djup på ungefär 1,5 meter. Vissa nyare tangentbordsdesign har dubbel tätning runt USB-anslutningar samt kantdesign som är vinklade för att leda vatten bort från känsliga komponenter i inre delarna. Denna typ av förbättringar har visat sig minska problem med vätskeinträngning med cirka 94 procent jämfört med vanliga tangentbord som inte har dessa skyddsfunktioner inbyggda.

Ökad efterfrågan på IP-certifierade tangentbord inom hälso- och sjukvård samt tillverkningsindustrin

Sjukhus och kliniker som följer CDC:s rengöringsstandarder behöver i dag tangentbord med IP68-certifiering eftersom de klarar alla dessa starka vätelösningsmedel. Under tiden föredrar tillverkningslinjer inom bilindustrin som hanterar läckage av kylvätska och oljor utrustning med IP66-certifiering istället. Enligt en nyligen genomförd studie av Verdantix från 2023 anser omkring två tredjedelar av personer som köper industriell utrustning att IP-klassningar idag är absolut nödvändiga för deras verksamhet. Det är en rejäl ökning jämfört med bara drygt 40 % för tre år sedan. Detta visar att fler industrier börjar inse att täta tangentbord faktiskt sparar pengar på lång sikt genom att hålla föroreningar borta från kritiska system.

Förlängda fördelar med yttäta tangentbord bortom skydd mot damm

Skydd mot vätskor, kemikalier och andra miljöföroreningar

Yttre tangentbordsförseglingar gör mer än att bara hålla borta damm, de tål också spill, rengöringsmedel och alla slags industriella kemikalier ganska bra. Tangentbord med en klassificering på IP66 eller IP68 skyddar mot att dessa skadliga frätande ämnen kommer in i elektroniken där de kan orsaka kortslutning eller slita ner material med tiden. Det faktum att dessa tangentbord klarar så många olika hot förklarar varför de flesta företag nuförtiden kräver förseglade modeller när de sätter upp arbetsstationer i miljöer som är känsliga för föroreningar. Enligt vissa branschrapporter har till och med cirka 90 % av företagen gjort övergången till denna typ av skydd för sin utrustning.

Förbättrad enhetslivslängd på grund av minskad inre slitage

Yttre tätningsmaterial gör undrar när det gäller att hålla borta smuts och skräp, och minskar mekanisk slitage på strömbrytare och kretsar med cirka 75 procent. Forskare undersökte cirka 12 tusen industriella tangentbord år 2022 och upptäckte något intressant. Tangentbord försedda med dessa speciella silikonnano-beläggningar klarade cirka 38 tusen fler tangenttryck innan de slutade fungera jämfört med vanliga utan skydd. För platser som sjukhus och laboratorier där utrustningen rengörs flera gånger om dagen, förlänger dessa tätningsmaterial tangentbordens livslängd med tre till fem år jämfört med standardmodeller. En sådan hållbarhet gör all skillnad när man arbetar i tuffa miljöer dag efter dag.

Lägre totala ägandekostnad i företags- och industriella miljöer

78 procents minskning av felkvoten hos IP-certifierade tangentbord leder till betydande driftbesparingar. Under en femårsperiod rapporterar anläggningar som använder tätnade tangentbord:

- 67% lägre kostnader för utbyte

- 41% färre driftstopp

- 83% minskade arbetskostnader för reparation

Dessa effektiviteter gör yttäta tangentbordssäkringar till en strategisk investering, särskilt för organisationer som hanterar stora flottor av arbetsstationer i krävande miljöer.

Innovationer som driver framtiden för täta tangentbordsdesign

Från gummiringar till nanobeklädnader: Utvecklingen av tätningsmaterial

Under de senaste tio åren har vi sett ganska stora förbättringar i tätnings teknologi, där dammblokering blivit mycket bättre - cirka 73 % förbättring enligt nyliga tester. Äldre silikontätningar kunde helt enkelt inte hantera dessa små partiklar under 5 mikron, men nu har vi dessa avancerade nanobeläggningar som faktiskt förvisar smuts på molekylär nivå. Många av dessa beläggningar innehåller också tillsatt antimikrobiellt material, vilket gör dem lämpliga för sjukhus och andra platser där renlighet är mycket viktig. Detta innebär alltså tunnare tätningar som fortfarande fungerar utmärkt, och som uppfyller det krävande IP68-standarden samtidigt som de upptar cirka 40 % mindre plats än tidigare. Tillverkare uppskattar detta eftersom det spar utrymme inom enheterna utan att minska skyddet.

Designförbättringar: Upprätthålla taktil återkoppling utan att kompromissa tätheten

Dessa dagar använder ingenjörer laserhålade mikrostrukturerade filmer tillsammans med tryckkänsliga ledande lager för att behålla den responsiva känslan när man skriver på förseglade tangentbord. Vissa studier från 2023 visade också ganska imponerande resultat - personer lyckades faktiskt skriva cirka 22 procent snabbare med dessa nyare modeller jämfört med de gamla membrantangentborden vi var vana vid. En annan smart lösning är flexibla polymertunnor som imiterar känslan hos traditionella mekaniska brytare men ändå behåller fullständig täthet mot föroreningar. Det gör dem väldigt användbara i platser som fabriker där damm alltid svävar runt, men arbetare ändå behöver exakt inmatning på tangentbordet hela dagen.

Att balansera ergonomi och skydd i moderna yttangents tätningslösningar

Många tillverkare förlitar sig nu på datormodeller för att finjustera tätningsformerna så att de fungerar bättre och känns mer komfortabla. Några av de senaste innovationerna inkluderar dessa vinklade skärmar i texturerade TPU-material som faktiskt leder bort spill utan att göra tangentborden högre. Detta löser ett tidigare verkligt problem där användare tvingades välja mellan god ergonomi och tillräcklig skyddsnivå. På fabriksgolven rapporterar arbetare att de upplever färre fall av överanvändningsskador sedan dessa mångsidiga konstruktioner introducerades. Siffrorna stöder detta också, med rapporter som visar en minskning med cirka 31 procent i sådana skador, samtidigt som skyddsklassen IP67 mot damm och smuts upprätthålls.

Vanliga frågor

Vad är IP-klassning, och varför är den viktig för tangentbord?

IP-klassificering står för Ingress Protection-klassificering och anger hur väl en enhet kan motstå intrång av damm och vatten. IP66 och IP68 är exempel, där den förra kan motstå kraftiga vattenstrålar och damm, medan den senare tillåter nedsänkning i vatten. För tangentbord säkerställer detta hållbarhet och funktionalitet i svåra miljöer.

Hur bidrar tätningsmaterial för tangentbord till enhetens långlivighet?

Tätningsmaterial för tangentbord skyddar interna komponenter genom att blockera damm, skräp, vätskor och kemikalier, minskar mekanisk slitage och förhindrar korrosion. Detta förlänger tangentbordens livslängd, särskilt i miljöer med ständig exponering för föroreningar.

Varför är täta tangentbord nödvändiga i industriella miljöer?

Täta tangentbord minskar reparationer orsakade av damm och partiklar, förbättrar enhetens tillförlitlighet och sänker underhållskostnaderna, vilket gör dem lämpliga för krävande industriella miljöer. De förhindrar kostsam driftstopp och säkerställer smidig drift.

Vilka material används i tätningsmaterial för tangentbord?

Material som används inkluderar silikontätningar, termoplastiska elastomerer, magnetiska tätningar med järnlegeringar och hydrofoba nanolager. Dessa material erbjuder skydd mot miljöpåverkan och förbättrar skrivupplevelsen.

Kan tätslagna tangentbord fortfarande ge taktil feedback?

Ja, avancerade konstruktioner med laserskurna mikrostrukturerade filmer och tryckkänsliga ledande lager bevarar den taktila feedbacken samtidigt som fullständig tätning säkerställs, vilket gör skrivandet responsivt och exakt.

Innehållsförteckning

- Vad är en yttålig tangentbordsförsegling och hur fungerar den?

- Försegla kontra oförsegla tangentbordsarkitekturer: Viktiga skillnader och prestanda

- Bevisad effekt av yttäta tangentbord i dammiga miljöer

- Tätningsmaterial för tangentbord på ytan och efterlevnad av miljöskyddsnormer

- Förlängda fördelar med yttäta tangentbord bortom skydd mot damm

- Innovationer som driver framtiden för täta tangentbordsdesign

-

Vanliga frågor

- Vad är IP-klassning, och varför är den viktig för tangentbord?

- Hur bidrar tätningsmaterial för tangentbord till enhetens långlivighet?

- Varför är täta tangentbord nödvändiga i industriella miljöer?

- Vilka material används i tätningsmaterial för tangentbord?

- Kan tätslagna tangentbord fortfarande ge taktil feedback?

EN

EN