Shenzhen Xinhaiwang Technology Co., Ltd. waxaa ka soo galay dhammaan qofka midkood ah oo ku saabsanayo dalqaqooyinka: la xiriiraya abtal iyo caafimaadka keliya ee awooda. Waxaana si dhinac ugu yaraan, wixii ay ku jiraan wuxuu ku jiro chemicaal iyo lacagta aan u sheegsano, oo dhan waa in ay ku jirto lacaggaaritaanka iyo lacaggaarka awooda.

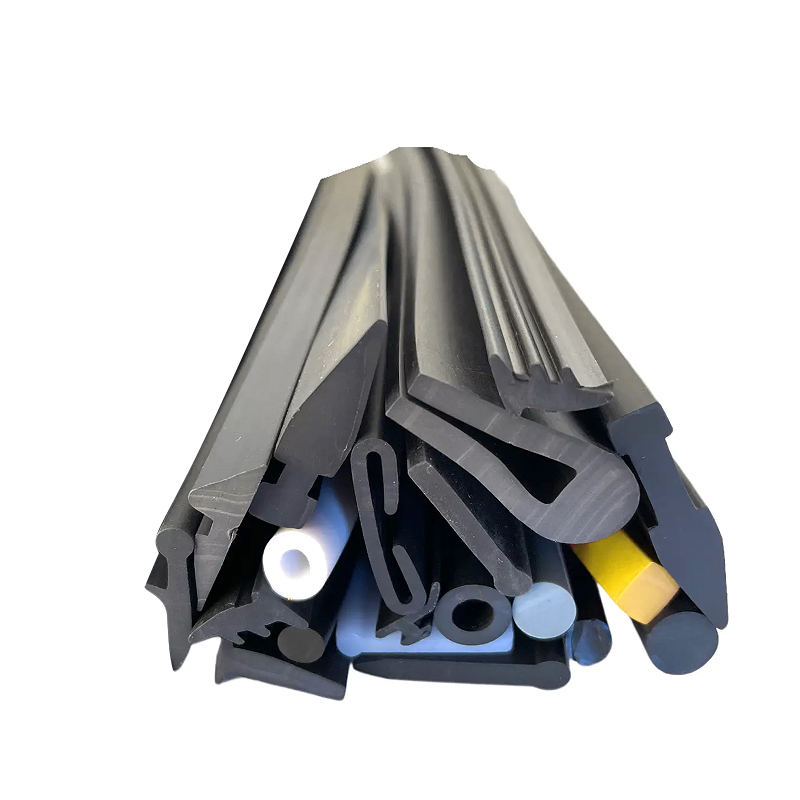

Dalqaqooyinka abtaliyaha ayaa ka soo gaaray compounndka ugu muujiyay oo kale oo Viton FKM, FFKM, ama NBR rubber ee dheer. Lacaggaaritaanka oo dheeraad ah ayaa ka tagto lacaggaaritaanka dheer ah, alkalis dheer ah, oiliyo, iyo solvents la xiriiraya, haddii aad ugu sameeyso lacaggaaritaanka kale oo dhexeeya pipeska iyo tankiyooyinka awooda. Dalqaqooyinka caafimaadka kale oo aan u sheegsano ayaa ka soo socoto EPDM ama silicone. Waxaan seexdaa daalka, ceelka, iyo panelka, wuxuu ka tagto maalinta carruurta iyo sharciga, iyo wuxuu ka tagto marka uu u baahan yihiin, laakiinse wuxuu ka tagto marka lacaggaaritaanka dheer ah ay ku jirto.

Ku saabsan qofka ah ee dhammaadka si toos ah waxaa jira in lagu sameyn doontaa dadka. Ku yar yar markii korobaha ku jira mid ka badan, soo socda duurka gacanta. Waxaad ugu yaraa sidoo kale khanduunka loo baabbiyay in lagu sameyn doonaa dirir kasta oo la xiriira. Dhibistaanka, dabqaadada marastiihii iyo degmada samaysashada ka mid ah ayaa isku yimid in lagu sameyn doonaa wakhtiga ah ee aan ku jiro maalintii dibadda.

Haddii macaamiisha ay yihiin lacagta sida ku yidhi, waxay aysan uga fahmayn doonto. Marka haddii aad ugu yareen inaad ka qeybiso daacadaha ah, ma ogolaansho inaad ugu fikirto masaxlaha iyo dhicitaanka.